flood, mold, starting over

pam_f

12 years ago

Related Stories

DISASTER PREP & RECOVERYHow to Combat Mold in a Flooded House

Before you rebuild or restore your water-damaged home, take these steps to keep mold at bay

Full Story

DECORATING GUIDESHow to Decorate When You're Starting Out or Starting Over

No need to feel overwhelmed. Our step-by-step decorating guide can help you put together a home look you'll love

Full Story

HOUZZ TOURSHouzz Tour: A Texas Home Gets a Healthy, Fresh Start

Mold eradication was just the beginning for this Austin family's home on a creek bed — toxins of all kinds now don't make it past the door

Full Story

DISASTER PREP & RECOVERYFamily’s New Style Rises in the Aftermath of a Flood

After their damaged walls are demolished, homeowners realize they like the open space and decide to keep it

Full Story

DISASTER PREP & RECOVERY7 Initial Steps for Dealing With Floodwater Damage

How you handle your flooded home and its contents can affect not only the damage level but also your personal safety

Full Story

MOST POPULARWhat to Do After a Hurricane or Flood

How you treat your home after a natural disaster can make all the difference in its future livability — and your own personal safety

Full Story

DECORATING GUIDESDecorating 101: How to Start a Decorating Project

Before you grab that first paint chip, figure out your needs, your decorating style and what to get rid of

Full Story

HOUZZ TOURSHouzz Tour: New Love and a Fresh Start in a Midcentury Ranch House

A Nashville couple, both interior designers, fall for a neglected 1960 home. Their renovation story has a happy ending

Full Story

MORE ROOMSFresh Start: Organizing Your Craft Room

10 ways to stash your arts and crafts supplies in style

Full Story

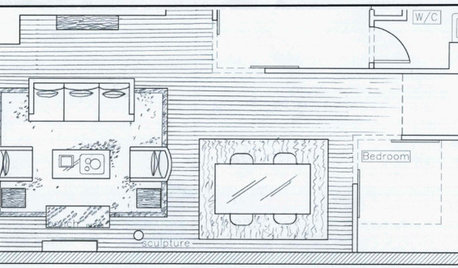

DECORATING GUIDES9 Planning Musts Before You Start a Makeover

Don’t buy even a single chair without measuring and mapping, and you’ll be sitting pretty when your new room is done

Full StoryMore Discussions

worthy

pam_fOriginal Author

Related Professionals

Belleville General Contractors · Deer Park General Contractors · Middletown General Contractors · New Milford General Contractors · Palatine General Contractors · Stillwater General Contractors · Austintown General Contractors · Wauconda Architects & Building Designers · Arlington Flooring Contractors · Framingham Flooring Contractors · Jacksonville Flooring Contractors · Mill Valley Flooring Contractors · Moorhead Flooring Contractors · Scottsboro Flooring Contractors · Woodbury Flooring Contractorsworthy