Do you have to have insulation?

Debbi Branka

11 years ago

Related Stories

GREEN BUILDINGInsulation Basics: Heat, R-Value and the Building Envelope

Learn how heat moves through a home and the materials that can stop it, to make sure your insulation is as effective as you think

Full Story

REMODELING GUIDESCool Your House (and Costs) With the Right Insulation

Insulation offers one of the best paybacks on your investment in your house. Here are some types to discuss with your contractor

Full Story

MATERIALSInsulation Basics: What to Know About Spray Foam

Learn what exactly spray foam is, the pros and cons of using it and why you shouldn’t mess around with installation

Full Story

GREEN BUILDINGInsulation Basics: Designing for Temperature Extremes in Any Season

Stay comfy during unpredictable weather — and prevent unexpected bills — by efficiently insulating and shading your home

Full Story

GREEN BUILDINGEcofriendly Cool: Insulate With Wool, Cork, Old Denim and More

Learn about the pros and cons of healthier alternatives to fiberglass and foam, and when to consider an insulation switch

Full Story

GREEN BUILDINGInsulation Basics: Natural and Recycled Materials

Consider sheep’s wool, denim, cork, cellulose and more for an ecofriendly insulation choice

Full Story

WINDOW TREATMENTSEasy Green: 9 Low-Cost Ways to Insulate Windows and Doors

Block drafts to boost both warmth and energy savings with these inexpensive but effective insulating strategies

Full Story

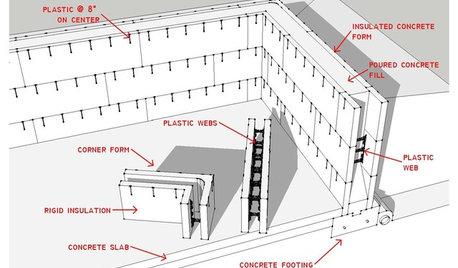

KNOW YOUR HOUSEKnow Your House: The Basics of Insulated Concrete Form Construction

Get peace and quiet inside and energy efficiency all around with this heavy-duty alternative to wood-frame construction

Full Story

GREEN BUILDINGHouzz Tour: Pickle Factory Now an Energy-Wise Live-Work Space

A charming but poorly insulated 1880s Philadelphia commercial building becomes a spacious energy-efficient home and studio

Full Story

KITCHEN DESIGNKitchen of the Week: Warming Trend in a 1920s Georgian

Renovation creates a formal yet functional and relaxed hub for entertaining — and takes care of the insulation problem

Full Story

worthy

Debbi BrankaOriginal Author

Related Professionals

Mashpee General Contractors · Melville General Contractors · Niles General Contractors · San Marcos General Contractors · Solon General Contractors · Martinsville Architects & Building Designers · Beacon Flooring Contractors · Belvedere Park Flooring Contractors · Elkridge Flooring Contractors · Harrisburg Flooring Contractors · Knoxville Flooring Contractors · Newburgh Flooring Contractors · Ocoee Flooring Contractors · Powder Springs Flooring Contractors · Skokie Flooring ContractorsDebbi BrankaOriginal Author

worthy

Debbi BrankaOriginal Author

worthy

Debbi BrankaOriginal Author

Debbi BrankaOriginal Author

worthy

Debbi BrankaOriginal Author

worthy

worthy

Debbi BrankaOriginal Author

worthy

Debbi BrankaOriginal Author