Rim joist retro insulation with spray foam?

pjb999

15 years ago

Featured Answer

Sort by:Oldest

Comments (10)

velvetfoot

15 years agoRelated Professionals

Burlington General Contractors · Dallas General Contractors · Hercules General Contractors · Langley Park General Contractors · Lewisburg General Contractors · Salem General Contractors · New Providence Interior Designers & Decorators · Riverside Architects & Building Designers · Auburn Flooring Contractors · East Palo Alto Flooring Contractors · Lansdale Flooring Contractors · Limerick Flooring Contractors · St. Louis Flooring Contractors · Whitman Flooring Contractors · Whittier Flooring Contractorspjb999

15 years agoandrelaplume2

15 years agovelvetfoot

15 years agotim52317

15 years agocountryboymo

15 years agopjb999

15 years agocountryboymo

15 years agoyupper_twcny_rr_com

12 years ago

Related Stories

MATERIALSInsulation Basics: What to Know About Spray Foam

Learn what exactly spray foam is, the pros and cons of using it and why you shouldn’t mess around with installation

Full Story

GREEN BUILDINGEcofriendly Cool: Insulate With Wool, Cork, Old Denim and More

Learn about the pros and cons of healthier alternatives to fiberglass and foam, and when to consider an insulation switch

Full Story

REMODELING GUIDESCool Your House (and Costs) With the Right Insulation

Insulation offers one of the best paybacks on your investment in your house. Here are some types to discuss with your contractor

Full Story

GREEN BUILDINGInsulation Basics: Natural and Recycled Materials

Consider sheep’s wool, denim, cork, cellulose and more for an ecofriendly insulation choice

Full Story

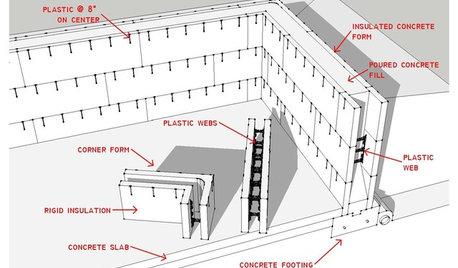

KNOW YOUR HOUSEKnow Your House: The Basics of Insulated Concrete Form Construction

Get peace and quiet inside and energy efficiency all around with this heavy-duty alternative to wood-frame construction

Full Story

GREEN BUILDINGHouzz Tour: Pickle Factory Now an Energy-Wise Live-Work Space

A charming but poorly insulated 1880s Philadelphia commercial building becomes a spacious energy-efficient home and studio

Full Story

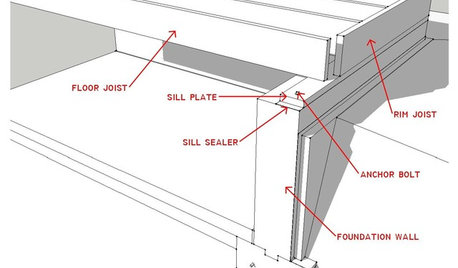

KNOW YOUR HOUSEKnow Your House: What Makes Up a Floor Structure

Avoid cracks, squeaks and defects in your home's flooring by understanding the components — diagrams included

Full Story

DIY PROJECTSHigh-End Look for Less: Make a Layered Headboard for $20

No sewing and sawing means no hemming and hawing; just gather some inexpensive materials and get going

Full Story

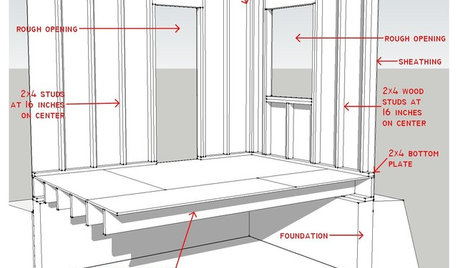

REMODELING GUIDESKnow Your House: Components of Efficient Walls

Learn about studs, rough openings and more in traditional platform-frame exterior walls

Full Story

COLORFUL HOMESMy Houzz: Colorful and Clever DIY Touches Fill an Alabama Farmhouse

Antiques, repurposed items and a whole lotta hard work give a family home cheery, personable style

Full Story

worthy