How to run duct for this hood?

nancyj

9 years ago

Related Stories

MONTHLY HOME CHECKLISTSNovember Checklist for a Smooth-Running Home

Prep for holiday entertaining and the onslaught of winter to enjoy a healthy home and a relaxed mood

Full Story

MONTHLY HOME CHECKLISTSSeptember Checklist for a Smooth-Running Home

Get ready to get cozy at home with snuggly blankets, well-stocked firewood, added insulation and more

Full Story

HOUSEKEEPINGMarch Checklist for a Smooth-Running Home

Get a jump on spring by spiffing up surfaces, clearing clutter and getting your warm-weather clothes in shape

Full Story

MONTHLY HOME CHECKLISTSFebruary Checklist for a Smooth-Running Home

Spend snowy days sprucing up, cleaning out and making your bedroom romance-ready

Full Story

MONTHLY HOME CHECKLISTSYour May Checklist for a Smooth-Running Home

Sail through the rest of spring by spiffing up your home and getting down in the backyard with friends

Full Story

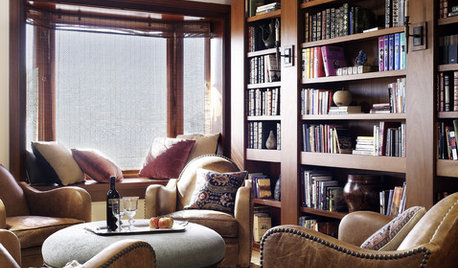

GUESTHOUSESHouzz Tour: A River (Almost) Runs Through It in Aspen

This guesthouse on a family compound has rustic charm, modern touches and dramatic river views

Full Story

5 Stunning Modern Range Hoods

Today's kitchen range hoods can look like sleek sculptures. Here's what to look for when you go shopping for one

Full Story

KITCHEN DESIGNHow to Choose the Right Hood Fan for Your Kitchen

Keep your kitchen clean and your home's air fresh by understanding all the options for ventilating via a hood fan

Full Story

KITCHEN DESIGNWhat to Know When Choosing a Range Hood

Find out the types of kitchen range hoods available and the options for customized units

Full Story

nancyjOriginal Author

kaseki

Related Professionals

Four Corners Kitchen & Bathroom Designers · Kalamazoo Kitchen & Bathroom Designers · Cherry Hill Kitchen & Bathroom Designers · Bethel Park Kitchen & Bathroom Remodelers · Creve Coeur Kitchen & Bathroom Remodelers · Lisle Kitchen & Bathroom Remodelers · Mesquite Kitchen & Bathroom Remodelers · Pasadena Kitchen & Bathroom Remodelers · Patterson Kitchen & Bathroom Remodelers · Port Orange Kitchen & Bathroom Remodelers · Black Forest Cabinets & Cabinetry · Key Biscayne Cabinets & Cabinetry · Central Cabinets & Cabinetry · University Park Cabinets & Cabinetry · Bellwood Cabinets & Cabinetryrwiegand

weissman

kaseki

nancyjOriginal Author

jdoenumber2

kaseki

weedmeister

callights

jdoenumber2