how does an induction stove compare to a normal coil electric?

judo_and_peppers

9 years ago

Related Stories

FUN HOUZZ10 Truly Irritating Things Your Partner Does in the Kitchen

Dirty dishes, food scraps in the sink — will the madness ever stop?

Full Story

REMODELING GUIDESBathroom Workbook: How Much Does a Bathroom Remodel Cost?

Learn what features to expect for $3,000 to $100,000-plus, to help you plan your bathroom remodel

Full Story

KITCHEN APPLIANCESFind the Right Cooktop for Your Kitchen

For a kitchen setup with sizzle, deciding between gas and electric is only the first hurdle. This guide can help

Full Story

VINTAGE STYLERevel in Retro With Vintage and New Kitchen Appliances

Give your kitchen old-fashioned charm with refrigerators and stoves that recall yesteryear — even if they were made just yesterday

Full Story

DISASTER PREP & RECOVERYMore Power to You: How to Pick the Right Generator

If your home's electricity goes, don't let it take your necessities with it — keep systems running with this guide to backup power

Full Story

LIFEHow to Prepare for and Live With a Power Outage

When electricity loss puts food, water and heat in jeopardy, don't be in the dark about how to stay as safe and comfortable as possible

Full Story

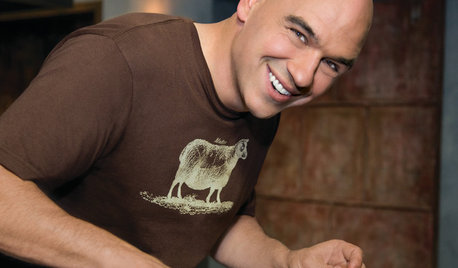

TASTEMAKERSPro Chefs Dish on Kitchens: Michael Symon Shares His Tastes

What does an Iron Chef go for in kitchen layout, appliances and lighting? Find out here

Full Story

KITCHEN DESIGN9 Popular Stovetop Options — Plus Tips for Choosing the Right One

Pick a stovetop that fits your lifestyle and your kitchen style with this mini guide that covers all the basics

Full Story

HOUSEKEEPINGCan-Do Cleaning Strategies for Busy People

While you dream of having a maid (to go with the cook and chauffer), this simplified cleaning routine can keep your real-world home tidy

Full Story

LIFEHow Do You Make Your Tea and Coffee in the Morning?

A morning cup is a must for many, and preparation comes in many guises. We look at coffee and tea habits across the Houzz community

Full StorySponsored

More Discussions

Fori

plllog

Related Professionals

Barrington Hills Kitchen & Bathroom Designers · Cuyahoga Falls Kitchen & Bathroom Designers · Fresno Kitchen & Bathroom Designers · Cherry Hill Kitchen & Bathroom Designers · Beach Park Kitchen & Bathroom Remodelers · Glendale Kitchen & Bathroom Remodelers · Honolulu Kitchen & Bathroom Remodelers · Oxon Hill Kitchen & Bathroom Remodelers · Port Charlotte Kitchen & Bathroom Remodelers · Sicklerville Kitchen & Bathroom Remodelers · Bon Air Cabinets & Cabinetry · National City Cabinets & Cabinetry · Radnor Cabinets & Cabinetry · Milford Mill Cabinets & Cabinetry · University Park Cabinets & Cabinetryjudo_and_peppersOriginal Author

weedmeister

plllog

User

jwvideo

herring_maven

westsider40

judo_and_peppersOriginal Author