New construction: venting and make-up air for 48'' range

aeliall

11 years ago

Related Stories

HEALTHY HOMEA Guide to Indoor Air Purifiers

Get the lowdown on air filtration systems for your house and the important ratings to look out for

Full Story

ROOM OF THE DAYRoom of the Day: Small Master Bath Makes an Elegant First Impression

Marble surfaces, a chandelier and a window seat give the conspicuous spot the air of a dressing room

Full Story

DECORATING GUIDES10 Ways to Hide That Air Conditioner

Feeling boxed in designing around your mini-split air conditioner? Try one of these clever disguises and distractions

Full Story

HEALTHY HOMEGet Cleaner Indoor Air Without Opening a Window

Mechanical ventilation can actually be better for your home than the natural kind. Find out the whys and hows here

Full Story

KITCHEN DESIGNKitchen Confidential: Amp Up Your Storage With Pullouts

See 12 types of cabinet pullouts that make your cooking and cleaning items easier to find and use

Full Story

THE HARDWORKING HOMESmart Ways to Make the Most of a Compact Kitchen

Minimal square footage is no barrier to fulfilling your culinary dreams. These tips will help you squeeze the most out of your space

Full Story

BATHROOM DESIGN12 Designer Tips to Make a Small Bathroom Better

Ensure your small bathroom is comfortable, not cramped, by using every inch wisely

Full Story

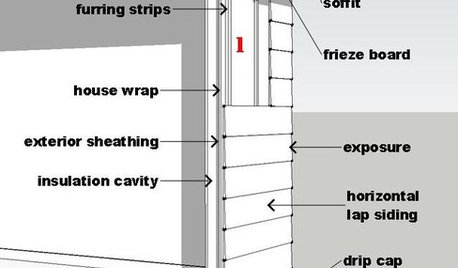

THE ART OF ARCHITECTUREArchitect's Toolbox: Rain Screens Up House Health

To thwart unwanted moisture and poor air quality in your home, think rain screens and drainage planes

Full Story

KITCHEN WORKBOOK4 Steps to Get Ready for Kitchen Construction

Keep your project running smoothly from day one by following these guidelines

Full Story

HOUZZ TOURSMy Houzz: Pretty Meets Practical in a 1920s Walk-Up

Creative styling gives an 800-square-foot rental such an inspired homey air, you might just miss the office in the living room

Full Story

BentZero

kaseki

Related Professionals

Commerce City Kitchen & Bathroom Designers · Flint Kitchen & Bathroom Designers · United States Kitchen & Bathroom Designers · Beaverton Kitchen & Bathroom Remodelers · Channahon Kitchen & Bathroom Remodelers · Chicago Ridge Kitchen & Bathroom Remodelers · Gilbert Kitchen & Bathroom Remodelers · Sicklerville Kitchen & Bathroom Remodelers · South Lake Tahoe Kitchen & Bathroom Remodelers · Winchester Kitchen & Bathroom Remodelers · Avocado Heights Cabinets & Cabinetry · Glendale Heights Cabinets & Cabinetry · Red Bank Cabinets & Cabinetry · Warr Acres Cabinets & Cabinetry · Watauga Cabinets & Cabinetrygluzd

kaseki