Should I use 50/50 or 60/40 Lead?

KimmyStar

11 years ago

Related Stories

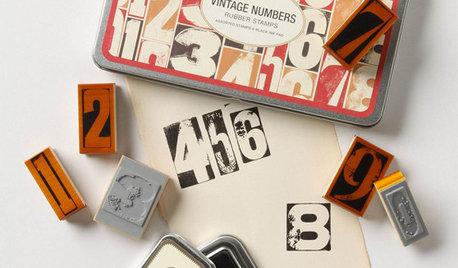

50 Great Gifts Under $50

Our favorite budget-minded holiday gifts for the design lovers on your list

Full Story

MOST POPULAR50 Shades of Gray

Gray is hotter than ever, thanks to a hit novel full of risks and dark secrets. Tell us: Which paint shade possesses you?

Full Story

MODERN HOMESHouzz Tour: ’50s Ranch Redo Could Be a Keeper

An experienced house flipper puts his creative talents to work on an L.A. remodel designed for his own family

Full Story

KITCHEN DESIGNPersonal Style: 50 Clever Real-Life Kitchen Design Details

Get ideas from savvy homeowners who have a knack for creating kitchens celebrating personal style

Full Story

FURNITUREHouzz Flip: 50 Comfy Chairs Every Dad Will Want to Sit In

Relax into Father’s Day with this collection of inviting recliners and lounge chairs

Full Story

FUN HOUZZHouzz Pets: 50 Cats Cozy Up at Home

Design-Loving Felines Have the Run of the House

Full Story

HEALTHY HOMEGet the Lead Out: Lead Safety at Home

Keep your family safe by properly testing for and dealing with lead in old painted surfaces, water and soil

Full Story

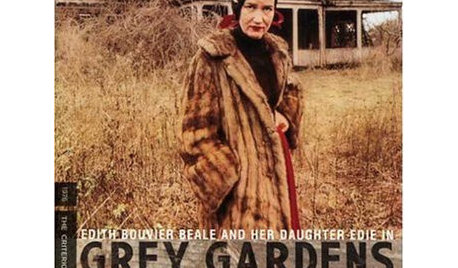

FUN HOUZZ10 Leading-Role Movie Houses

Architecture and interior design steal the show in these 10 house-focused flicks

Full Story

MIDCENTURY STYLEHouzz Tour: Back to the ’50s in the Heart of Bordeaux

A great laboratory for ideas, the interior of this house in Bordeaux has been renovated according to 1950s Scandinavian design

Full Story

REMODELING GUIDESHouzz Tour: Turning a ’50s Ranch Into a Craftsman Bungalow

With a new second story and remodeled rooms, this Maryland home has plenty of space for family and friends

Full StorySponsored

Related Discussions

Ready mixed 50:1 or 40:1 in OSH

Q

Were you born in the 40's or 50's?

Q

How to get $1. 00 charitable value for 50 - 60 cents

Q

240 50 cycle used in US, 60 cycle

Q